Quality & Sourcing

We support professional buyers with a structured approach to sourcing Turkish honey and bee products. The objective is simple: deliver the right specification, with repeatable batch quality, and documentation that clears—before goods leave Turkey.

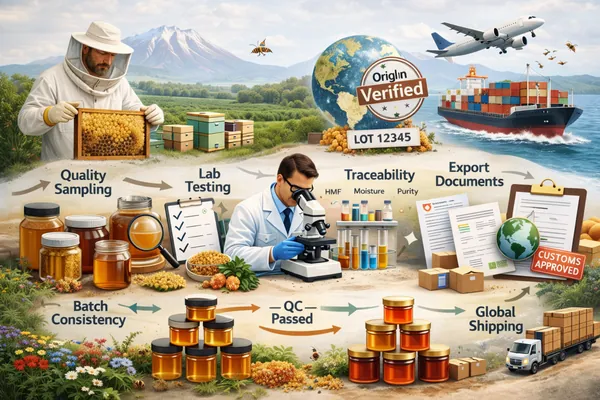

Whether you buy for retail, foodservice, or manufacturing, the risks are similar: variable seasonal supply, inconsistent sensory profiles, adulteration concerns, packaging misfit, and document mismatches at import. Our sourcing workflow is designed to reduce these failure points using vetted partners, sampling, targeted testing, traceability controls, and shipment-ready documentation.

- Specification fit (flavor, color, moisture, HMF, diastase)

- Adulteration risk management and practical controls

- Batch consistency planning for repeat orders

- Packaging suitability for your market and channel

- Documentation accuracy for smooth customs clearance

- Bulk: drums / pails for ingredient use and repacking

- Retail: jars, squeeze bottles, portion formats (by program)

- Bee products: moisture-controlled pollen, propolis extracts, chilled/frozen royal jelly (where required)

Vetted sourcing across Turkey

Turkey offers wide floral diversity and strong beekeeping traditions, but professional buying requires more than origin. We cooperate with established producers and packers and match supply based on your category, volume, sensory profile, and compliance needs. When required, we arrange sampling and validation before finalizing the shipment plan.

Honey varieties

Blossom, pine honey, and monofloral types (e.g., chestnut, citrus, lavender, thyme, linden) as well as regional selections. We focus on consistent sensory profile and parameter alignment for your use case.

- Retail-ready and bulk formats

- Color/taste targets and crystallization expectations

- Private label support: positioning and claims review

Bee products

Propolis, bee pollen, royal jelly, and functional blends with clear handling and storage guidance. For sensitive items, we prioritize freshness and process controls.

- Moisture and freshness controls for pollen

- Food-grade packaging planning

- Batch documentation, storage, and shelf-life guidance

Capacity alignment

We align supply with your planning horizon—trial orders, seasonal purchases, and ongoing replenishment programs—while maintaining visibility on MOQs, lead times, and packing schedules.

- MOQ and lead-time clarity

- Lot planning and reservations (program-based)

- Logistics readiness and dispatch coordination

What we ask for at inquiry stage

The more precise your input, the faster we can match supply and reduce back-and-forth. If some items are unknown, we propose options.

- Product type(s) and intended use (retail, foodservice, ingredient)

- Target market and destination port/country

- Preferred packaging format and labeling needs

- Volume, purchase cadence, and target lead time

- Your required COA fields or import requirements (if available)

Supplier qualification and partner selection

“Vetted” means we do not treat all supply as equal. We qualify producers and packers against practical criteria that matter for buyers: consistency, process hygiene, packaging capability, documentation discipline, and responsiveness when issues arise.

Capability fit

We assess whether the partner can reliably meet your format, volume, and packing schedule—especially for multi-SKU programs.

- Bulk vs. retail packing capability

- Label application and cartonization options

- Lead-time realism during peak seasons

Process & hygiene discipline

We prioritize clean handling practices and documentation discipline aligned with export expectations.

- Traceable batch records

- Basic hygiene controls and handling procedures

- Packaging material suitability

Quality consistency

We aim to reduce “good once, variable later” outcomes by focusing on repeatability and lot planning.

- Sensory profile repeatability

- Parameter stability over time

- Clear lot selection for repeat orders

Quality assurance workflow

Quality is managed as a process, not a claim. We start with your specification, validate with samples, confirm packaging suitability, and keep documentation aligned with the lot actually shipped. For sensitive products (especially bee products), handling and storage are treated as part of “quality,” not an afterthought.

Specification capture

We capture your target profile (sensory + numeric parameters), use case, labeling requirements, and any restricted/required claims. If you do not have a formal spec, we propose a buyer-ready one based on the product and destination market norms.

Sampling & validation

Pre-shipment samples can be arranged for sensory review and lab checks (as requested). This step reduces the risk of packing a lot that later fails internal approval or import checks.

Lot control

We map the lot intended for shipment, maintain packing date visibility, and coordinate consistency checks for repeatability. For retail programs, we also confirm label/pack details to prevent mismatches at receiving.

Documentation lock

COA and export documents are aligned to the exact lot and the final shipment configuration (pack counts, weights, HS details, consignee naming, and other critical fields).

Typical parameters buyers request

We can align testing and COA fields to your internal spec or import requirements.

- Moisture, HMF, diastase activity

- Electrical conductivity (where relevant)

- Color, taste, aroma (sensory profile)

- Residues / contaminants (as required)

- Microbiology for relevant bee products

Packaging-fit checks

Viscosity, crystallization behavior, and fill/closure options are reviewed for your channel. For retail, we also discuss shelf presentation, cap types, and carton stability.

View packaging optionsRepeat order continuity

If you are building a brand or distribution line, we can plan lots and reserves to keep taste, color, and key parameters stable across replenishments.

- Preference mapping (your “approved profile”)

- Lot selection and reserve planning (when feasible)

- Consistent COA structure for internal filing

Testing, COA, and buyer confidence

For professional buying decisions, a Certificate of Analysis should be meaningful: it should match your requested fields, be associated with the lot shipped, and be formatted so your team can approve and file it quickly. We can support a “minimum viable COA” for trials and expand the panel for programs that require deeper verification.

COA field alignment

We align COA fields to your spec (or destination market expectations) before sampling and dispatch. This reduces last-minute rework and avoids missing fields that delay import clearance or internal approval.

Lot-to-document match

We keep paperwork tied to batch identifiers and shipment mapping to reduce mismatches at customs, receiving, and internal QA review.

Practical risk checks

We support checks that matter for your channel—retail stability, foodservice handling, or manufacturing inputs—so you are not over-testing low-risk items and under-testing high-risk items.

When to request expanded testing

Buyers typically expand panels when risk or exposure increases—new supplier, large volume, sensitive market, or a private label launch.

- First-time supplier qualification

- Large seasonal buy with long shelf life expectations

- High scrutiny retail markets or audits

- Ingredient use in regulated finished goods

How we keep COAs “usable”

A COA is only valuable if it is clear, consistent, and easy to validate against your spec.

- Consistent parameter naming and units

- Batch identifier visibility on documents

- Clear dating: sampling / analysis / packing

- Structured files for procurement & QA teams

Adulteration risk management (practical controls)

Adulteration risk is a commercial and reputational exposure for professional buyers. We support practical controls aimed at reducing risk: sourcing discipline, batch selection visibility, and testing alignment to your program’s risk level. If your destination market has specific requirements, we will align the approach to those expectations.

Risk-based sourcing

We prioritize supply where batch control and documentation discipline support repeatability and transparency.

- Clear lot selection and packing date visibility

- Supplier discipline on process and paperwork

- Channel fit (ingredient vs. retail expectations)

Testing strategy fit

We do not apply one generic panel to every program; we align to your risk level and market norms.

- Minimum trial panel vs. expanded program panel

- Lot-specific documentation and controls

- Consistency checks for repeat orders

Document discipline

Many issues come from mismatched lots and paperwork. We keep the chain tight from lot selection to shipment set.

- Lot identifiers mapped to COA and shipment

- Reduced “last-minute substitution” risk

- Clear corrective steps if changes occur

Traceability and sourcing transparency

We support traceability at a practical level: batch tracking, packing records, and origin documentation appropriate to your program. If you require additional disclosures (e.g., region narratives, supplier declarations), we can discuss feasibility based on product category and supplier structure.

Batch mapping

- Lot identifiers and packing dates

- Shipment mapping to invoice/packing list/COA

- Repeat-order consistency planning

- Program notes: approved profile, substitutions policy

Origin support

- Turkey origin documentation (as required)

- Regional storytelling inputs (where applicable)

- Label and claim alignment guidance

- Country-of-origin and traceability statement support (program-based)

Traceability for different buyer types

Traceability needs differ by channel. We will align the document set and visibility level to how you buy and how you are audited.

- Importers/distributors: document completeness, HS alignment, receiving clarity

- Retail/private label: batch continuity, label consistency, complaint readiness

- Manufacturing: parameter stability and lot approval workflow support

Handling, storage, and shelf-life planning

Product integrity depends on correct handling. We support buyers with practical guidance on storage conditions, temperature exposure risk, and packaging fit—especially relevant for bee products that are moisture- or temperature-sensitive.

Honey stability

We discuss crystallization expectations, viscosity, and retail presentation—so your team is prepared for normal honey behavior.

- Crystallization behavior by variety

- Temperature exposure considerations during shipping

- Best practices for warehousing and rotation

Bee pollen moisture control

Moisture is a primary risk driver for pollen. Packaging and storage guidance helps protect freshness and reduce spoilage risk.

- Moisture awareness and storage discipline

- Food-grade packaging planning

- Receiving checks and shelf-life handling

Royal jelly & propolis handling

Certain formats may require controlled temperature or specific packaging. We discuss feasibility based on your route and destination.

- Storage expectations by format

- Packaging and closure planning

- Shipment planning aligned to handling needs

Export documentation support

Documentation is often the difference between smooth clearance and costly delays. We support buyers with structured document sets and responsive revisions when needed—aligned to the shipment configuration and consignee requirements.

- Commercial invoice, packing list

- Certificate of Origin (as required)

- Health / sanitary documentation (where applicable)

- COA and product specification sheets

- Label support: ingredients, nutrition, allergen statements (as applicable)

- Shipment mapping: packs, weights, and identifiers for receiving

Common document failure points we help prevent

- Mismatch between packed quantities and packing list

- Missing or inconsistent product naming and HS details

- COA not matching the shipped lot / incorrect dates

- Consignee details inconsistent across documents

- Label elements misaligned with the agreed pack plan

Best for

- Importers and distributors

- Retail private label programs

- Foodservice and hotel supply

- Food manufacturers using honey as an ingredient

Shipping coordination (practical)

We coordinate shipment readiness so packaging, palletization, and documents are aligned before dispatch. Share your preferred Incoterms and destination details in your inquiry.

- Carton and pallet planning (program-based)

- Weight/volume estimates for planning

- Dispatch timing aligned with your receiving windows

Frequently requested clarifications

Can you support private label requirements?

Yes. Share your target positioning, packaging preferences, and label requirements. We will propose feasible options and communicate lead times and MOQs clearly. For private label programs, we recommend aligning COA fields and label elements early to avoid last-minute revisions.

Do you provide samples before shipment?

When requested, we arrange sampling for sensory review and relevant lab checks. This is typically done before finalizing packing and dispatch plans. For repeat programs, we can define an approval workflow so each replenishment stays within the agreed profile.

Which tests should we request on the COA?

It depends on the product type and your market. Common fields include moisture, HMF, diastase, conductivity (for some varieties), and residue/micro checks as required. If you share your destination and compliance expectations, we will help structure a practical test plan.

How do you support batch consistency for repeat orders?

We start by defining your approved profile (sensory + parameters), then plan lot selection and packing schedules to maintain continuity. Where feasible, we support lot planning so replenishments remain within the agreed range and documentation stays consistent.

Can you align documents to our internal naming and filing system?

Yes. If you provide a COA template, product naming conventions, and consignee details, we can structure the document set to match your internal workflow and reduce manual corrections at receiving and customs.

Share your spec—get a matched supply plan

Send your target product, volume, packaging, and destination. We will reply with feasible options and a documentation-ready plan. If you have a COA template or internal specification, include it for the fastest alignment.